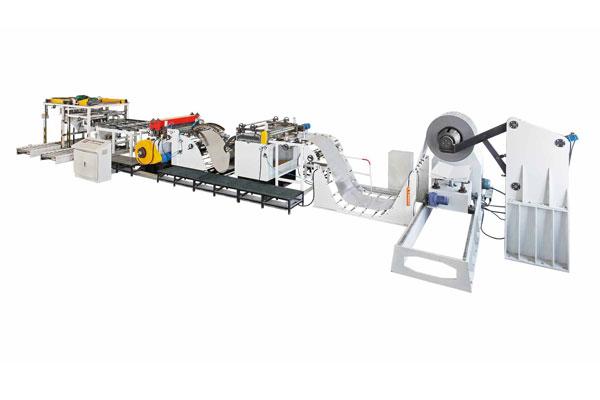

KX-1200 Uncoiling Leveling Shearing Production Line

This product is suitable for uncoiling, leveling, high-precision cutting, and receiving of tinplate coils of different specifications. It becomes a flat sheet of required length. Indispensable cutting equipment.

The production line is mainly composed of: uncoiler, pinch machine, leveling machine, roller conveying, shearing machine or wave shearing machine, belt conveying, receiving machine, electrical control cabinet and so on.The electric control element adopts imported PLC program control system and AC servo system, which has the characteristics of accurate cutting precision, high production efficiency, and counting function.

This machine has two types: semi-automatic and fully automatic uncoiling and shearing. As long as the manual uncoiling is changed to a hydraulic automatic uncoiling machine, the automatic uncoiling process can be realized.

The main technical parameters:

| Cut Max Width | 1200(mm) |

| cut length | 1200(mm) |

| shear thickness | 0.15~0.5(mm) |

| coil weight | 12(t) |

| maximum shear rate | 70(p/min) |

| line speed | 60(m/min) |

| Maximum stacking weight | 2.5(t) |

| Leveling roll diameter | Ø55(mm) |

| Number of rollers of leveler | 21(pcs) |

| Shearing accuracy | ±0.15(mm) |

| Total weight of equipment | 10(t) |

| Total length of equipment arrangement | 17.78(m) |